Calculation of floor filling materials

Calculation of self-leveling floors

Specify dimensions in millimetres

X - width of room

X - width of roomY - room length

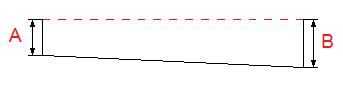

Spend the difference heights in the four corners of the space, in pixels, of the A, B, C, D.

To do this, use the building level.

Set the minimum thickness of the filling. This amount will be automatically applied to the lowest point of the room.

As a result of the volume of materials needed will be calculated in cubic metres and a height of at the corners of the room.

The program considers the amount of material for filling of sex taking Delta heights in the corners.

You will be able to more accurately count the cost of the materials.

Calculation of floor filling materials

The main advantage of filling in the special vyravnivaûŝiesâ mixtures which it used, create an even and smooth surface without any extra effort on your part. That is why such floors today have gained special popularity.Pour the floors can be independently. All that is required is to know the length and width of a premise, its height, in the corners, as well as the minimum thickness of a layer of fill, then our program will calculate for you the amount of material to fill a given differential heights.

The benefits of flood of floors

1. The surface of the sexes equal, without cracks and backlashes.2. The lifespan of the self-leveling floors comes to 40-50 years.

3. Wear Resistance.

4. Does not require special maintenance.

Floor preparation

Stack the deck floor is quite simple, so many prefer to do it yourself without resorting to specialists. But there are some subtleties.So, before laying the floor you need to prepare the room. To do this remove the old flooring, baseboards and door. The floor surface is levelled. This can be done using a special šlifovočnoj machine or iron brush. Then, if there are cracks in the floor, you must open the triangular scraper.

Remember that if you are going to lay the filler on top of a wooden floor, a special reinforced mesh.

After that, with the help of Reiki is measured by the angle of the floor. According to these measurements on the walls made the mark, to which the height of the floor will be poured. At this height, plus 2.5 centimeters, the walls are cleaned from stucco and other finishing materials.

Then the floor over cleansed and obezžirivaetsâ using a special powder.

Now Paul is aligned with whitewashed mortar, cracks and crevices, vyglaživaûtsâ roughness. After that the floor should be primed. And the preparatory phase is over. You can start laying the floor.

Laying of floor water inlet

To pour the floor evenly take Assistant who will be mixing the solution while you're pouring.Prepare the mortar according to the instructions on the package. The solution was uniform, do not fill the tank at once all the water. Let this be a big part of it. Mix the solution in it. For this it is best to use an electric drill with a special nozzle. And only when the solution will turn into a homogeneous mass, pour the remaining water.

The floor is poured in the direction of the door, opposite to the entrance into the room. Pour mixture in portions after each levelling the surface with the help of needle roller. It helps remove air bubbles, which can get into the solution, and ensure an even coating.

By pouring one portion to another time period should not be longer than 10 minutes.

During drying, and is 3-6 hours depending on the brand of solution should avoid draughts and variations in temperature.

Author of the project: Dmitry Zhitov

Author of the project: Dmitry Zhitov