Bulk floor materials chhiar dan

Self-leveling floor chhiar dan

Dimensions chu millimeter-ah tarlan rawh

X - room zau zawng a ni

X - room zau zawng a niY - room sei zawng a ni

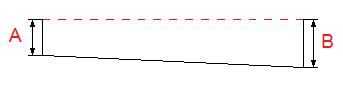

Room kil paliah, point hrang hrangah a san zawng inthlauhna chu teh rawh A, B, C, D.

Chutiang ti tur chuan building level hmang la.

Screed thickness tlem ber chu set rawh.

Chumi avang chuan thil tul volume chu cubic meter-a chhut a ni ang a, room kil hrang hranga san zawng pawh set a ni ang.

Program hian self-leveling floor atana materials volume chu a chhut ang a, corner-a san zawng inang lo chu a ngaihtuah ang.

Materials man hi dik zawkin i chhut thei ang.

Bulk floor materials chhiar dan

Self-leveling floor thatna ber chu a atana hman tur special leveling compound te hian i lam atanga thawhrimna dang awm lovin a flat leh smooth surface a siam a ni. Chuvangin tûn laiah chuan chutiang floor-te chuan a lar hle a ni.Floor te chu nangmah ngeiin i fill thei ang. Chumi atana mamawh chu room sei zawng leh zau zawng, a sir lama a san zawng hriat a ni a, chubakah fill layer thickness tlem ber hriat a ni a, chu mi hnuah kan program chuan material volume to chu a chhut thei ang che fill, a san zawng danglamna ngaihtuah chungin.

Pored floors atanga hlawkna awm thei

1. Chutiang floor chunglam chu a flat a, seam leh gap a awm lo.2. Self-leveling floor-a service life hi kum 40-50 vel a ni.

3. Wear resistance a ni.

4. Enkawl bik a ngai lo.

Floor buatsaih dan tur

Filler floor dah hi a awlsam khawp mai, chuvangin mi tam tak chuan mahni chauha tih an duh zawk a, specialist te pan lovin. Mahse hetah hian subtleties thenkhat a awm.Chuvangin, lei i dah tan hmain room chu i buatsaih hmasa phawt a ngai a ni. Chutiang ti tur chuan flooring hlui, skirting board leh kawngkhar te chu lakchhuah a ni. Floor surface chu a level a ni. Hei hi grinding machine bik emaw, thir brush emaw hmangin tih theih a ni. Tichuan, leiah hian crack a awm chuan triangular scraper hmanga hawn tur a ni.

Thing chungah filler floor i dah dawn a nih chuan special mesh hmanga tihchak hmasak tur a ni tih hre reng ang che.

Chumi hnuah chuan rail hmangin floor inclination angle chu an teh thin. Heng tehna ang hian bang-ah hian eng san zawngah nge lei chu a leih dawn tih chhinchhiahna siam a ni. Hetianga san zawng, plus 2.5 centimetre-ah hian bangte chu plaster leh finishing material dang hmangin an tifai a ni.

Tichuan a hnuai chu an tifai leh a, special powder hmangin an degreased leh a.

Tunah chuan lei chu mortar hmangin an level a, crack leh crevices te chu smeared a ni a, irregularities te chu smoothed out a ni. Chumi hnuah chuan floor chu primed a ngai a ni. Tin, he inbuatsaihna stage-ah hian a zo tawh bawk. Floor chu i laying tan thei bawk.

Filling floor a ni

Floor chu a ruala theh tur chuan i leih laiin assistant pakhatin mortar chu mix tir rawh.Package instruction angin solution chu buatsaih rawh. Solution homogeneous taka awm theih nan tui zawng zawng chu vawi khatah container chhungah theh vek suh. Hei hi a lian ber ni rawh se. A chhungah chuan solution chu mix rawh. Chutiang ti tur chuan electric drill, nozzle bik nei hman a tha ber. Tin, solution chu homogeneous mass-a a chan chauhvin tui la awm chu a chhungah theh lut rawh.

Kawngkhar lam hawiin, pindan luhna kawngkhar lehlam kil atang chuan lei chu a luang chhuak a. Chumi hnuah chuan a then hrang hrangin theh lut la, spiked roller hmangin a chunglam i level apiangin theh lut rawh. Hei hian solution chhunga air bubble lut thei zawng zawng chu a paih chhuak thei a, even coating a awm theih nan a pui bawk.

Portion pakhat atanga a dang theh chhuah atanga hun chhung chu minute 10 aia rei lo tur a ni.

Floor a vawt lai hian darkar 3-6 vel a ni a, solution brand a zirin room chhunga draft leh temperature inthlak danglam loh tur a ni.

Author of the project: Dmitry Zhitov

Author of the project: Dmitry Zhitov